Χρήση τεχνολογιών Cloud-Edge-IoT με στόχο την βελτιστοποίηση της ενεργειακής κατανάλωσης.

Φεβρουάριος 26, 2025Composting is the natural biological process of breaking down organic materials—like food scraps, leaves, and manure—into a dark, crumbly, nutrient-rich substance/fertiliser called compost. It’s essentially nature’s way of recycling. Composting happens through the activity of microorganisms (bacteria, fungi) and macroorganisms (worms, insects), which:

- Feed on organic matter (carbon and nitrogen-rich materials)

- Use oxygen and moisture to thrive

- Generate heat as a byproduct of decomposition

In the context of the OpenAgri project we developed and currently evaluate Digicompost, an IoT-based solution for remotely monitoring and optimising the fermetantion conditions.

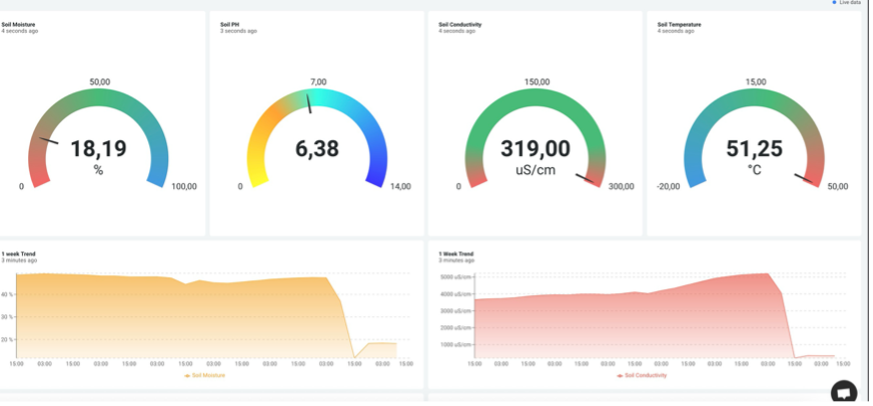

Thus, we installed LoRaWAN sensors for monitoring Temperature, Soil Moisture, pH and LoRaWAN eValves for automatically actuating the irrigation system. This ensures that the fermentation process is maintained within the optimal conditions while field visits are reduced to absolutely necessary.

The DigiCompost solution is currently applied in Farmers Fresh fruit and vegetables processing factory in Cyprus.

Instead of transferring byproducts and other vegetables wastes to landfills, the raw materials are collected in piles at the processing site. However, composting vegetables is quite challenging given their high level of moisture and Nitrogen excess.

The process didn’t start well, and this was evident by the relatively low temperature recordings (less than 25C). It was necessary to add more carbon-rich materials. After “fine tuning” the mix the bacteria kick-started the process and we are currently measuring temperatures more than 50C – a clear indication that we got into the “🔥 Thermophilic phase 🔥”. It is the phase that rapid breakdown is taking place and heat kills pathogens.

Now a new problem that is detected is that the compost moisture dropped below 20% and fermentation might stop.

Based on a predefined rule, low soil moisture sensors recordings are triggering the activation of irrigation sprinklers -for 4 minutes- to increase moisture and cool down the piles… 🧊

Now, our DigiCompost sensor recordings analytics indicate that the fermentation process is in line with the expected sequence of measurements and that about 50-55 days remain until the vegetables waste will turn into a nutrient rich fertilizer.

But this is not enough!

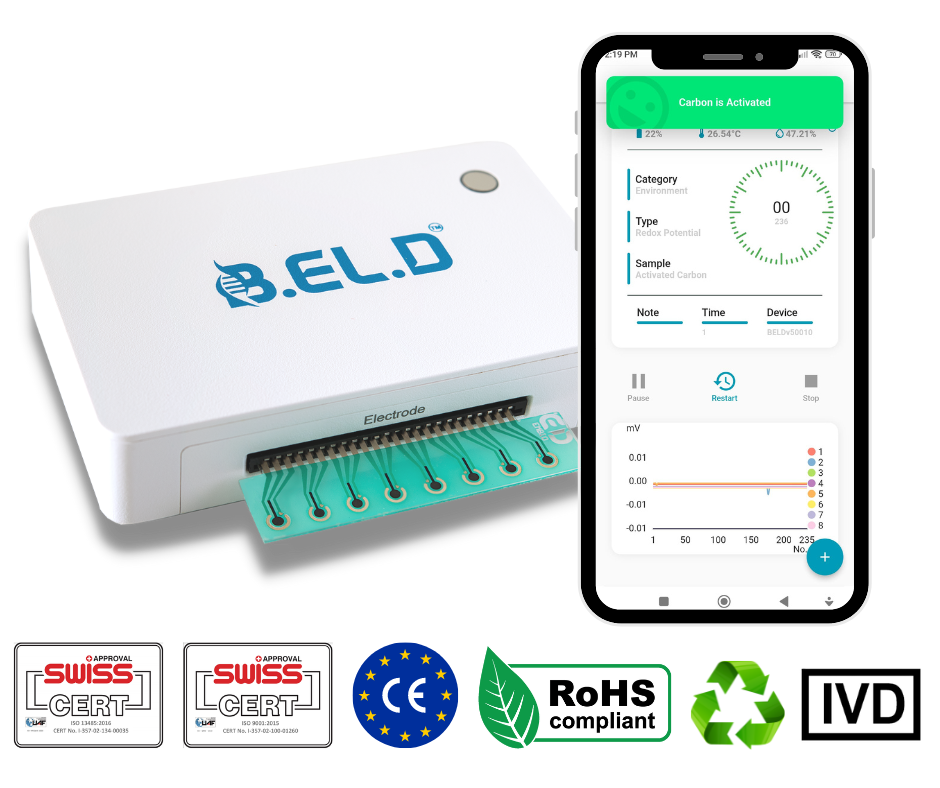

Here is where the biotech experts by EMBIO Diagnostics with their handheld sensing device are needed. EMBIO has developed an easy-to-use portable BioElectric-chemical analysis sensor (BELD) that allows the on-site and in near-real-time compost sampling and estimation of the three essential nutrients (Nitrogen-Phosphorus-Potassium). This allows to further fine tune the process and confirm the nutrient content of the fertiliser.

A final note… we are currently evaluating two versions of the DigiCompost solution: A cloud based that all data are transmited and hosted in cloud computing servers and an edge-computing based where data storage and processing is realised by a small computer located in the fruit processing factory.

So, stay tuned, more news about innovative composting solutions are coming soon!